Supmersible Aerator SP SERIES a result of rapid industrial development, enormous quantity

of wastewater were generated, in the meantime large quantities of household waste water were also resulted from our daily lives.

All these have affected the living quality and damaged the environmental ecology. For this purpose, KIRA has been making every endeavor in researching and developing waste water treatment equipment for years, now KIRA produces a series of industrial submersible aerators and surface aerators, which are capable of effectively treating wastewater and enable BOD & COD rate in the wastewater to meet standard.

These areators have been widely used in industrial wastewater treatment plant and small-scale municipal sewage treatment plant inside and outside the country.

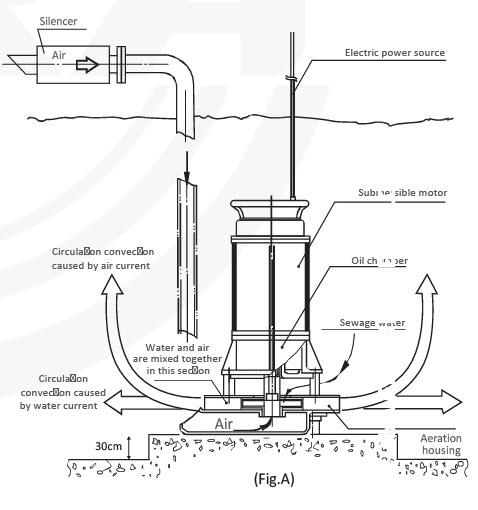

Submersible aerator-SP utilizes the rotation of the impeller

coupled directly to the motor to create a centrifugal force, which

makes local low pressure suck in water. Meanwhile the entrance

of the Impeller results in vacuum to draw air from atmosphere.

Water and air mix in the channel of aeration housing. The air-

water-mixture current is discharged speedily by the centrifugal

force.

Due to the water spurting extremely strong, make the fluid create convection and circulation effectively. Moreover the air becomes tiny bubbles.

On the one hand the bubbles rise slowly, on the other hand the atmosphere oxygen is dissolved in water.

Because the bubbles are tiny and numberless, their surface area is large, it makes the oxygen transfer rate per unit BHP higher than other types of aerator.

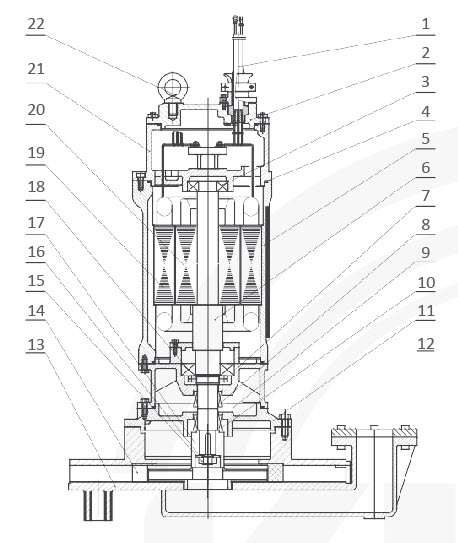

| NO. | Name | Material | |

|---|---|---|---|

| GB | JIS | ||

| 1 | Cable | 2RNCT | 2RNCT |

| 2 | The motor cover | HT200 | FC200 |

| 3 | Ballbearing | - | - |

| 4 | O-ring | NBR | NBR |

| 5 | Motor casing | HT200 | FC200 |

| 6 | Mainshaft | 2Cr13 | SUS420J1 |

| 7 | Bracket | HT200 | FC200 |

| 8 | Mechanical seal | C-Al203 | C-Al203 |

| 9 | Lubricant | ISOVG32 | ISOVG32 |

| 10 | Mechanical seal | SIC-SiC | SIC-SIC |

| 11 | Oil cover | HT200 | FC200 |

| 12 | Aeration housing | HT200 | FC200 |

| 13 | Bottom cover of aeration housing | HT200 | FC200 |

| 14 | Entrance panel board | ZGOCr18Ni9 | SUS304 |

| 15 | Screw | A2-70 | A2-70 |

| 16 | Gasket | 3Cr13 | SUS420J2 |

| 17 | Impeller | ZGOCr18Ni9 | SUS304 |

| 18 | Ballbearing | - | - |

| 19 | Stator | - | - |

| 20 | Rotor | - | - |

| 21 | Motor cover | HT200 | FC200 |

| 22 | Lifting rings | 0Cr18Ni9 | SUS304 |

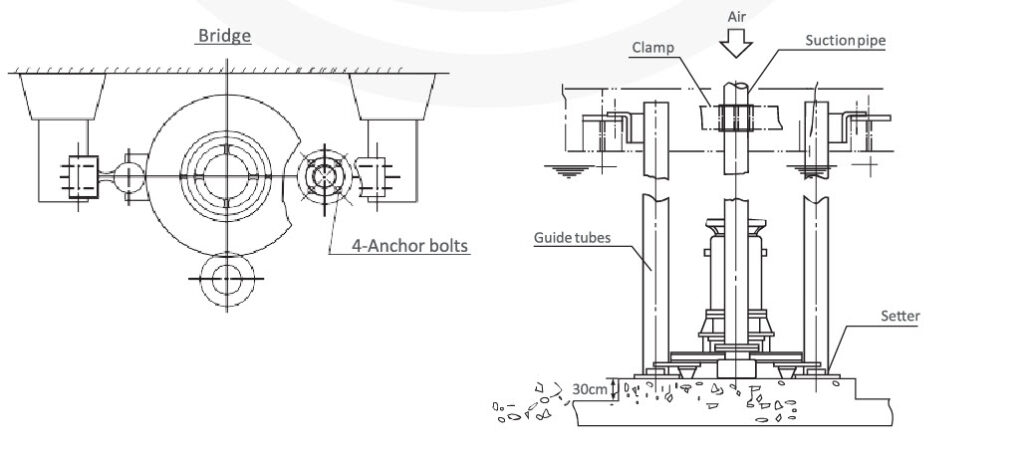

For better and easier maintenance of the aerator, following instructions shall be noticed:

| Type | Power | Operation range (m.) |

Min-max water depth (m.) |

Air inlet pipe diameter (mm.) |

The maxium intake of air (m3/h) |

Oxygentransfer capacity (kgO2/h) |

Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|

| hp | kW | |||||||

| SP41.5-1.5 | 2 | 1.5 | 1.0-2.0 | 1.0-3.0 | 40 | 40 | 2-1 | 135 |

| SP42.2-2 | 3 | 2.2 | 2.5-5.0 | 1.0-4.0 | 50 | 60 | 3-2 | 147 |

| SP44-2.5 | 5.5 | 4 | 3.0-6.0 | 1.0-4.0 | 65 | 90 | 5-3 | 160 |

| SP45.5-2.5 | 7.5 | 5.5 | 3.5-7.0 | 1.0-4.0 | 65 | 150 | 9-5 | 315 |

| SP47.5-3 | 10 | 7.5 | 4.5-9.0 | 1.5-4.5 | 80 | 170 | 13-7 | 320 |

| SP411-3 | 15 | 11 | 5.0-10.0 | 1.5-4.5 | 80 | 260 | 18-8 | 368 |

| SP415-4 | 20 | 15 | 5.8-11.5 | 1.5-4.5 | 100 | 340 | 23-10 | 385 |

| SP418.5-4 | 25 | 18.5 | 5.9-11.8 | 2.0-5.0 | 100 | 360 | 29-14 | 432 |

| SP422-4 | 30 | 22 | 6.0-12.0 | 2.0-5.5 | 100 | 440 | 36-19 | 456 |

| SP430-6 | 40 | 30 | 7.3-14.5 | 2.0-6.0 | 150 | 510 | 41-21 | 998 |

| SP437-6 | 50 | 37 | 7.5-15.0 | 2.0-6.0 | 150 | 600 | 52-22 | 1080 |

| SP445-6 | 60 | 45 | 7.8-15.5 | 2.0-6.0 | 150 | 700 | 62-25 | 1155 |

| SP455-6 | 75 | 55 | 8.0-16.0 | 2.0-6.0 | 150 | 780 | 82-40 | 1200 |

| Type | Dimensions (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | I | J | R | |

| SP41.5-1.5 | 165 | 300 | 365 | 252.5 | 40 | 173 | 576 | 617 | 30 |

| SP42.2-2 | 170 | 350 | 430 | 302.5 | 50 | 176 | 670 | 698 | 30 |

| SP44-2.5 | 170 | 350 | 430 | 302.5 | 65 | 176 | 670 | 732 | 30 |

| SP45.5-2.5 | 223 | 435 | 540 | 362.5 | 65 | 242 | 800 | 855 | 32.5 |

| SP47.5-3 | 223 | 435 | 540 | 362.5 | 80 | 243 | 800 | 855 | 32.5 |

| SP411-3 | 223 | 435 | 540 | 362.5 | 80 | 248 | 800 | 950 | 32.5 |

| SP415-4 | 223 | 435 | 540 | 362.5 | 100 | 252 | 800 | 955 | 32.5 |

| SP418.5-4 | 223 | 435 | 540 | 362.5 | 100 | 252 | 800 | 1120 | 32.5 |

| SP422-4 | 223 | 435 | 540 | 362.5 | 100 | 252 | 800 | 1120 | 32.5 |

| SP430-6 | 338 | 600 | 740 | 475 | 150 | 346 | 1108 | 1448 | 39 |

| SP437-6 | 338 | 600 | 740 | 475 | 150 | 367.5 | 1108 | 1467.5 | 39 |

| SP445-6 | 338 | 600 | 740 | 475 | 150 | 367.5 | 1108 | 1467.5 | 39 |

| SP455-6 | 338 | 600 | 740 | 475 | 150 | 367.5 | 1108 | 1702.5 | 39 |

| Type | Max water depth (m.) |

Shape and dimensions (m.) | ||

|---|---|---|---|---|

| Round (Diameter) | Square | Rectangular | ||

| SP41.5-1.5 | 3 | 3.5 | 3.1 x 3.1 | 2.5 x 3.8 |

| SP42.2-2 | 4 | 4.8 | 4.2 x 4.2 | 3.4 x 5.2 |

| SP44-2.5 | 4 | 6.6 | 5..8 x 5.8 | 4.8 x 7.1 |

| SP45.5-2.5 | 4 | 8 | 7.1 x 7.1 | 5.8 x 8.7 |

| SP47.5-3 | 4.5 | 9.8 | 8.7 x 8.7 | 7.1 x 10.6 |

| SP411-3 | 4.5 | 12.5 | 11.1 x 11.1 | 9.1 x 13.6 |

| SP415-4 | 4.5 | 12.5 | 11.5 x 11.5 | 9.1 x 13.6 |

| SP418.5-4 | 5 | 12.5 | 11.8 x 11.8 | 9.7 x 14.5 |

| SP422-4 | 5.5 | 12.5 | 12.0 x12.0 | 9.7 x 14.5 |

| SP430-6 | 6 | 16 | 14.5 x 14.5 | 12.5 x 17.0 |

| SP437-6 | 6 | 16 | 15.0x 15.0 | 13.0 x 17.5 |

| SP445-6 | 6 | 16 | 15.5 x 15.5 | 13.0 x 17.5 |

| SP455-6 | 6 | 16 | 16 x 16 | 13.5 x 18.0 |

| Note: To achieve higher efficient operation, oversize particles and long fibers should not in the aeration tank. | ||||

© 2022 KIRA PUMP MANUFACTURING CO., LTD.