Submersible Sewage Pump NP SERIES

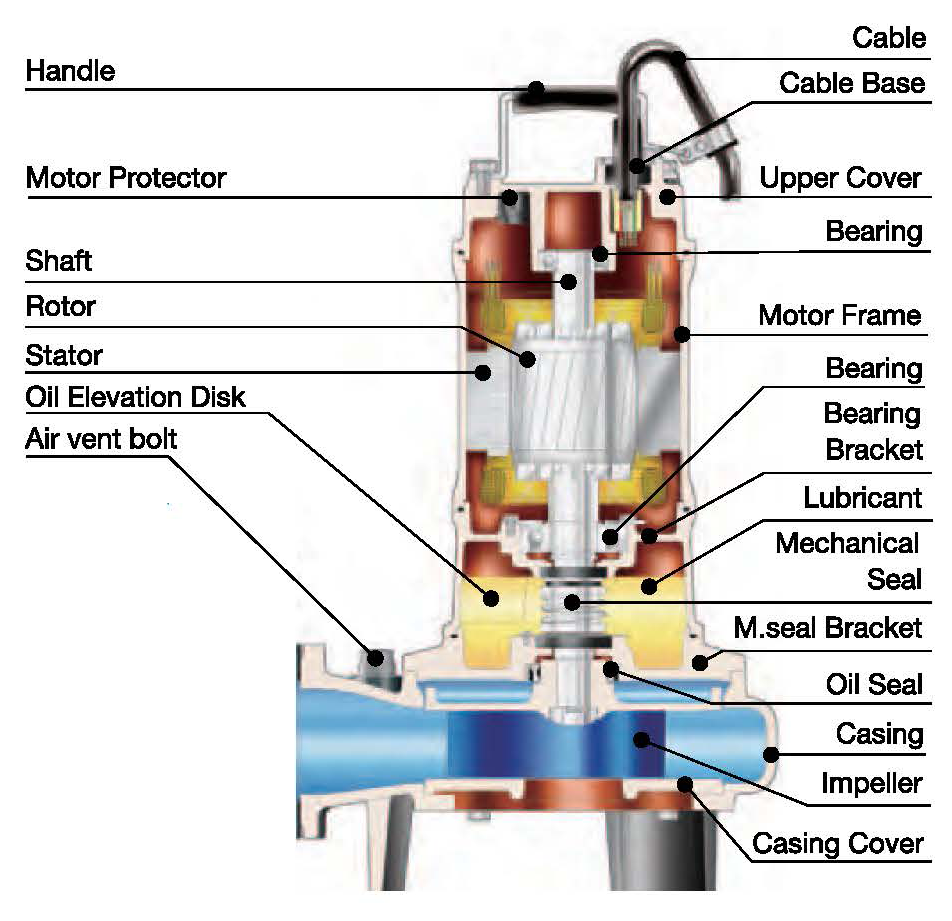

All stator coils are insulated by quality varnish under the automatic production line. This ensures the best insulation and durability.

All pumps are equipped with double mechanical seal. Strong abrasion resistant mechanical seal composes of best grade silicon carbide to ensure the best seal performance.

All cables are seals firmly by rubber cup and filled with thick layer of epoxy resin at the cable entry. This expoxy resin prevents moisture entering through cable into motor caused by suction force in motor chamber.

High solids expoxy coating is used to provide good resistance to wastewater, water contain chemical* or sea water*. Expoxy coating reduces speed of corrosion and extends life span of pump.

* Resistance is up to mild level of chemical and sea water. Please consult your dealer for intense level liquid.

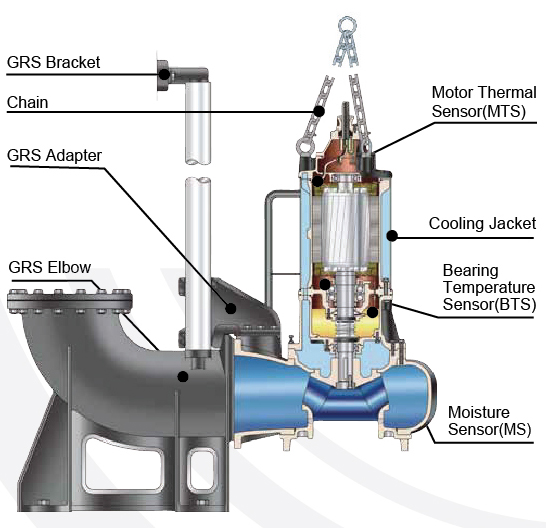

From 22kW and up, pump comes with special jacket covering motor frame. Even though pump is all submerged, high power of motor create high heat during operation and shorten pump life. Cooling down is a key. When pump is operating, water goes to inlet and run between cooling jacket and motor frame to reduce temperature of motor before it is flused out.

To level up the extra care of pump, special sensor can be placed to monitor temperture of bearing. BTS must be connected to indicator of temperature control in control box*. When temp of bearing exceeds the pre-setting temp of indicator of temperature control, the relay switch will cut off power supply.

*User must prepare indicator and control box to use this function.

** This is non-standard and can be used with pump 22kW and up.

The motor protector will be activated and cut power off automatically when motor run in abnormal electric current or temperature. This auto-cut protector will be self reset the motor when it returns to normal. The auto-cut protector is installed in the motor and no outside connection required. It is standard equipment in pump up to 7.5kW. From 20kW and up, motor thermal sensor (MTS) is applied. It is embedded in each phase of stator winding. When abnormal temperature is detected, this sensor will trip and relay switch in control box* will cut off the power supply.

* User must prepare relay and control box to use this function.

This special electrode sensor will detect water leakage into oil chamber. Its purpose to prevent mechanical seal damage or burnt from lack of lubrication ability. When water leakage is detected, the relay switch in control box will cut off power supply. This parts is standard component in pump from 20KW and up)

* User must prepare relay and control box to use this function.

All pumps are filled with non toxic lubricant to follow company philosophy “JUNSUI” or pure water for good environment. This lubricant is food grade FDA standard, eco friendly and low impact on aquaculture farming.

This useful parts will allow continuous operation of pump even in very dirty water. Pump contains semi-open or enclosed channel impeller having enough space to pass solid matters to minimize clogging. This usefully extend the life of pump. dealer for intense level liquid.

| Detail (Discharge 2"-4") | |||

|---|---|---|---|

| Motor | Body | ||

| Frequency | 50/ 60Hz | Impeller | Non-clog type (Channel, Semi open or Vortex) |

| Phase | Three-phase (Single-phase upon request) | FC200 | |

| Motor | Dry submersible induction motor | M.seal | Double mechanical seal |

| 2P (3,000 rpm)/ 4P (1,500 rpm) | CA/CE & SiC/SiC | ||

| Insulation | Class B (up to 2.2kW)/ Class F (3.7 - 20kW) | Bearing | Ball type |

| Protection | IP68 | Upper Cover | FC200 |

| Motor Protection | Auto-cut protector (built-in) up to 7.5kW | Motor Frame | FC200 |

| MTS from 11kW | Shaft | Stainless steel | |

| Water Leak Protection | Moisture sensor from 11kW | Casing | FC200 |

| Cable | VCT or PNCT or H07RN-F or SJOW/SOW | ||

| Application Liquid Temp Wastewater, Sewage and Farming 0 - 40 C (32 - 104 F) | |||

| Model | Motor Output kW | Pole/ Phase | Discharge inch (mm) | Impeller Type |

Start Method | Head m | Flow | Solid Passage mm | Weight kg | Cable m | Accessories | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elbow | Guide Rail | ||||||||||||

| m3/min | m3/h | ||||||||||||

| NP2.4-2S | 0.4 | 2P/ 1ø | 2" (50) | Vortex | Capacitor | 6 | 0.15 | 9 | 35 | 19 | 10 | BP-96 | TP-50 |

| NP2.4-2 | 0.4 | 2P/ 3ø | 2" (50) | Vortex | Direct | 6 | 0.15 | 9 | 35 | 18 | 10 | BP-96 | TP-50 |

| NP2.8-2S | 0.75 | 2P/ 1ø | 2" (50) | Vortex | Capacitor | 8 | 0.2 | 12 | 35 | 20 | 10 | BP-96 | TP-50 |

| NP2.8-2 | 0.75 | 2P/ 3ø | 2" (50) | Vortex | Direct | 8 | 0.2 | 12 | 35 | 19 | 10 | BP-96 | TP-50 |

| NP21.5-3S | 1.5 | 2P/ 1ø | 3" (80) | Semi-Open | Capacitor | 8.5 | 0.6 | 36 | 35 | 37 | 8 | BP-130 | TP-80 |

| NP21.5-3 | 1.5 | 2P/ 3ø | 3" (80) | Semi-Open | Direct | 8.5 | 0.6 | 36 | 35 | 33 | 8 | BP-130 | TP-80 |

| NP22.2-3 | 2.2 | 2P/ 3ø | 3" (80) | Semi-Open | Direct | 12.5 | 0.6 | 36 | 35 | 35 | 8 | BP-130 | TP-80 |

| NP23.7-3 | 3.7 | 2P/ 3ø | 3" (80) | Semi-Open | Direct | 20.5 | 0.6 | 36 | 32 | 48 | 8 | BP-150A | TP-80D |

| NP25.5-4 | 5.5 | 2P/ 3ø | 4" (100) | Semi-Open | Direct | 21.5 | 1 | 60 | 30 | 75 | 10 | BP-175(145) | TP-100(80BH) |

| NP27.5-4 | 7.5 | 2P/ 3ø | 4" (100) | Semi-Open | Direct | 28 | 1 | 60 | 30 | 81 | 10 | BP-175(145) | TP100(80BH) |

| NP211-4 | 11 | 2P/ 3ø | 4" (100) | Semi-Open | Star-Delta | 39.5 | 1 | 60 | 30 | 90 | 10 | BP-175(145) | TP100(80BH) |

| Model | A | D | H | Accessories | Remark | |

|---|---|---|---|---|---|---|

| Elbow | Guide Rail | |||||

| NP23.7-3 | 498 | 290 | 576 | BP-150A | - | Figure 5 |

| NP23.7-3 | 680 | 290 | 628 | - | TP-80D | Figure 6 |

| Model | A | D | H | Accessories | Remark | |

|---|---|---|---|---|---|---|

| Elbow | Guide Rail | |||||

| NP25.5-4 | 596 | 345 | 689 | BP-175(145) | - | Figure 7 |

| NP27.5-4 | 596 | 345 | 689 | BP-175(145) | - | |

| NP25.5-4 | 860 | 345 | 719 | - | TP-100(80)BH | Figure 8 |

| NP27.5-4 | 860 | 345 | 719 | - | TP-100(80)BH | |

| Detail (Discharge 6"-8") | |||

|---|---|---|---|

| Motor | Body | ||

| Frequency | 50/ 60Hz | Impeller | Non-clog type (Channel) |

| Phase | Three-phase | FC200 | |

| Motor | Dry submersible induction motor | M.seal | Double mechanical seal |

| 4P (1,500 rpm)/ 6P (1,000 rpm) | CA/CE & SiC/SiC | ||

| Insulation | Class F | Bearing | Ball type |

| Protection | IP68 | Upper Cover | FC200 |

| Motor Protection | MTS | Motor Frame | FC200 |

| Shaft | Stainless steel | ||

| Casing | FC200 | ||

| Water Leak Protection | Moisture sensor | Cable | VCT or PNCT or H07RN-F |

| Application LiquidTemp |

Wastewater, Sewage and Farming 0 - 40 C (32 - 104 F) |

||

| Model | Motor

Output kW |

Pole/ Phase | Dischargeinch (mm) | Impeller Type |

Start Method | Head m |

Flow | Solid Passage mm | Weight kg | Cablem | Accessories | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| m3/min | m3/h | Elbow | Guide Rail | ||||||||||

| NP411-6 | 11 | 4P/ 3ø | 6" (150) | Enclosed Channel | Star-Delta | 15.5 | 2.5 | 150 | 76 | 164 | 10 | BP-240(165) | TP-150(100)BH |

| NP415-6 | 15 | 4P/ 3ø | 6" (150) | Enclosed Channel | Star-Delta | 21 | 2.5 | 150 | 76 | 176 | 10 | BP-240(165) | TP-150(100)BH |

| NP422-6 | 22 | 4P/ 3ø | 6" (150) | Enclosed Channel | Star-Delta | 27.5 | 2.5 | 150 | 76 | 229 | 10 | BP-240(165) | TP-150(100)BH |

| NP411-8 | 11 | 4P/ 3ø | 8" (200) | Enclosed Channel | Star-Delta | 10 | 4.5 | 270 | 75 | 221 | 8 | BP-290 | TP-200 |

| NP415-8 | 15 | 4P/ 3ø | 8" (200) | Enclosed Channel | Star-Delta | 14 | 4.5 | 270 | 75 | 234 | 8 | BP-290 | TP-200 |

| NP422-8 | 22 | 4P/ 3ø | 8" (200) | Enclosed Channel | Star-Delta | 18 | 4.5 | 270 | 76 | 220 | 10 | BP-290(240) | TP-200E(150A) |

| Model | Motor Output kW |

Pole/Phase | Discharge inch (mm) | Impeller Type |

Start Method | Head m | Flow | Solid Passage mm | Weight kg | Cable m | Accessories | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elbow | Guide Rail | ||||||||||||

| m3/min | m3/h | ||||||||||||

| NP422-10 | 22 | 4P/ 3ø | 10" (250) | Enclosed Channel | Star-Delta | 14 | 7.0 | 420 | 60 | 710 | 10 | BP-355 | TP-250 |

| NP430-10 | 30 | 4P/ 3ø | 10" (250) | Enclosed Channel | Star-Delta | 17 | 7.0 | 420 | 60 | 681 | 10 | BP-355 | TP-250 |

| NP437-10 | 37 | 4P/ 3ø | 10" (250) | Enclosed Channel | Star-Delta | 22 | 7.0 | 420 | 60 | 691 | 10 | BP-355 | TP-250 |

| NP622-14 | 22 | 6P/ 3ø | 14" (350) | Enclosed Channel | Star-Delta | 6.5 | 14 | 840 | 120 | 823 | 10 | BP-455 | TP-350 |

| NP630-14 | 30 | 6P/ 3ø | 14" (350) | Enclosed Channel | Star-Delta | 8.5 | 14 | 840 | 120 | 833 | 10 | BP-455 | TP-350 |

| NP637-16 | 37 | 6P/ 3ø | 16" (400) | Enclosed Channel | Star-Delta | 7.5 | 20 | 1200 | 120 | 965 | 10 | BP-510(445) | TP-400(350) |

| NP645-16 | 45 | 6P/ 3ø | 16" (400) | Enclosed Channel | Star-Delta | 10.5 | 18 | 1080 | 120 | 970 | 10 | BP-510(445) | TP-400(350) |

© 2022 KIRA PUMP MANUFACTURING CO., LTD.