Submersible Sewage Pump CP SERIES

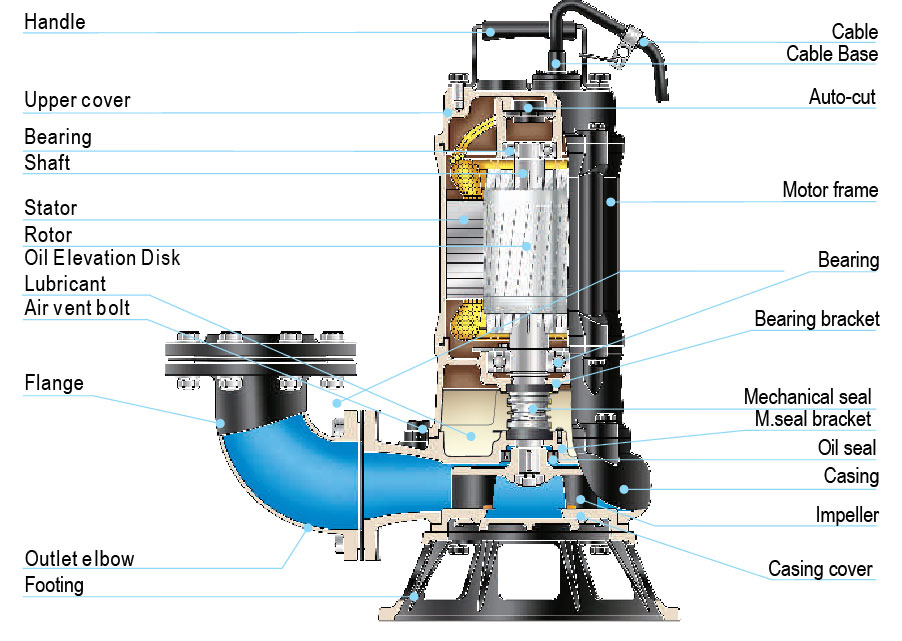

Automatic On/Off motor protector to prevent motor burn out due to high temperature and excess amperage draw.

The tungsten carbide edge, on the impeller vanes, shreds against the inner cutting blades to break down destructible solids into small pieces to prevent clogging in the pump.

The heat hardened casing cover is designed to withstand abrasions.

ELBOW/GUIDE RAIL SYSTEMS

Pump can be installed with 90° Elbow with Flang or GRS quick coupling system, for safe installation, removal, replacement and mintenance purpose.

| ITEM | DESCRIPTION | |

|---|---|---|

| Limits of Use | Liquid Temp. | 0-40°C (32-104 °F) |

| Applications | Wastewater ㆍSewage | |

| Frequency | 50Hz | |

| Type | Motor | 2P (3000rpm). Dry Motor |

| Insulation | Class F (2~5HP)ㆍClass H (7.5~15HP) | |

| Protection | IP68 | |

| Protector | Auto-cut (2~10HP) ㆍMTS&MS (15HP) | |

| Bearing | Ball type | |

| M.Seal | Double M.Seal | |

| Impeller | Semi-open | |

| Material | Upper Cover | FC-200 |

| Motor Frame | FC-200 | |

| Shaft | SUS403 (2~10HP)ㆍSUS420J2 (15HP) | |

| M.Seal | CA/CE & SiC/SiC | |

| Casing | FC-200 | |

| Impeller | FC200 + Tungsten | |

| Casing Cover | FC200 + Heat | |

| Footing | FCD450 | |

| Cable | VCT/HVCT or HO7RN-F or SJOW/SOW | |

| Optional | Pumps can be customized to fit specifications | |

| MODEL | Output | Discharge | Phase |

Start Method | Head | Standard | Solid Passage | Weight (kg) | Dimensions (mm.) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

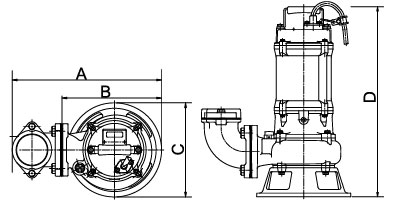

| HP(kW.) | Inch (mm.) | 1 ø | 3 ø | A | B | C | D | ||||||||

| ø | m. | m3/min | m3/h | mm | 1 ø | 3 ø | |||||||||

| CP21.5-3S | 2(1.5) | 3″(80) | 1 | Capacitor | 7.5 | 0.06 | 36 | 62 | 37 | 33 | 417 | 275 | 260 | 576 | 521 |

| CP21.5-3 | 2(1.5) | 3″(80) | 3 | Direct | 7.5 | 0.06 | 36 | 62 | 37 | 33 | 417 | 275 | 260 | 576 | 521 |

| CP22.2-3S | 3(2.2) | 3″(80) | 1 | Capacitor | 11 | 0.06 | 36 | 62 | 40 | 35 | 417 | 275 | 260 | 603 | 521 |

| CP22.2-3 | 3(2.2) | 3″(80) | 3 | Direct | 11 | 0.06 | 36 | 62 | 40 | 35 | 417 | 275 | 260 | 603 | 521 |

| CP23.7-3 | 5(3.7) | 3″(80) | 3 | Direct | 19 | 0.06 | 36 | 62 | - | 48 | 498 | 305 | 290 | - | 578 |

| CP25.5-4 | 7.5(5.5) | 4″(100) | 3 | Direct | 19.5 | 1 | 60 | 67 | - | 75 | 596 | 373 | 345 | - | 689 |

| CP27.5-4 | 10(7.5) | 4″(100) | 3 | Direct | 26 | 1 | 60 | 67 | - | 81 | 596 | 373 | 345 | - | 689 |

| CP211-4 | 15(11) | 4″(100) | 3 | Y-D | 37 | 1 | 60 | 67 | - | 91 | 596 | 373 | 345 | - | 729 |

© 2022 KIRA PUMP MANUFACTURING CO., LTD.